Craft to Mass Production

A concept piece derived from the combination of a university submissions.

An internal project where I was asked to discover the nature of play and derive a concept that could be produced using a single material. I later had to redesign my original concept for mass production.

What makes play? How does a product influence play? What is good play? What is bad?

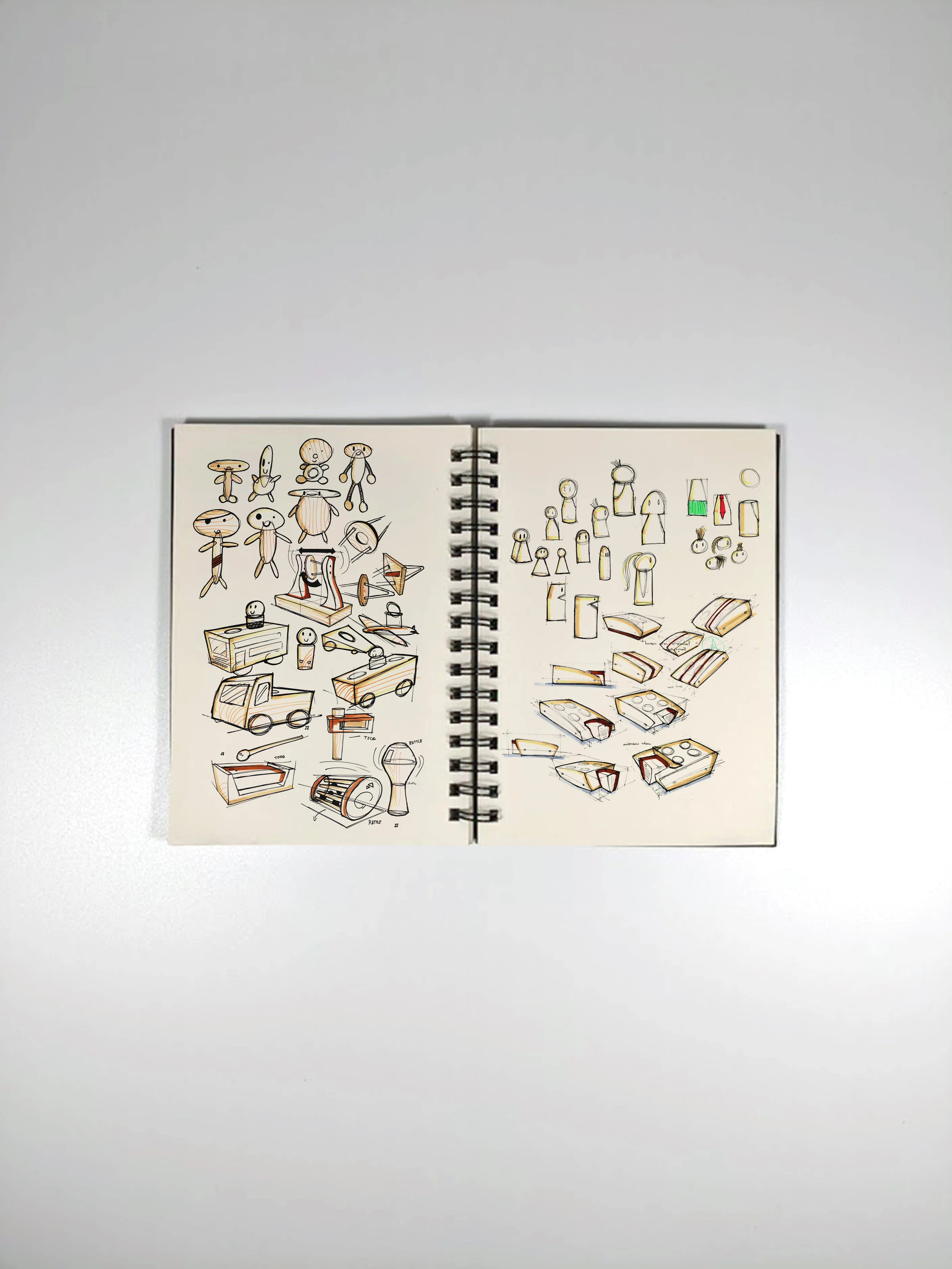

Ideation

With the brief in hand I was able to start constructing a response.

There were only two main restrictions on this project. One, it must be made of wood. Two, it must be a toy. From this, I considered what forms celebrate the natural beauty of wood and its characteristics.

TOUCH WOOD

The initial response was constructed from wood with other natural materials included to enhance functionality.

This hand-made model used different species of woods with tonal variations to accent the outcome. A felt liner was used to decrease the tolerances on the seats as well as a contrasting texture on the underside of the body. The wheel pins are friction fit in place to aid easy repair, likewise, the figures are doweled with the hair adhered in place.

MASS PRODUCTION

After completing the first concept I was asked to redesign my original response for mass production.

The first step I took was identifying an audience. I decided to go for top-end designer toys. With this target market in mind, I could then consider materials and processes that fit within the adapted brief. To make this toy suitable for mass production, I had to consider the limitations of producing a product from a single material and what materials are better suited to both the production process and the consumer.

ORTHOGRAPHIC

A technical drawing that shows draft angles and details that relate to the effects of adapting the original concept for manufacture.

EXPLODED VIEW - A demonstration of understanding of the nature of mass production.

In total, two materials are present throughout this outcome, the first being a matte black ABS. Ribs and bosses are present throughout the lower base with holes accurately positioned for the wheels to snap-fit into. The figure components are friction fit using the shown mating section. All the ABS components would be injection moulded. Whereas I intended for the second material, a Scots Pine, to be CNC carved. The body would be finished with clear natural shellac to keep the wood pure and honest.

Toy from Craft to Mass Production by Jacob Cave | Spring 2020 | Coventry University

For full submission project ‘HERE’